NAME: AgSnO2 Wire

Can be customized

AgSnO2/AgSnO2In2O3

Product Material

AgSnO2In2O3

General Description

AgSnO 2 and AgSnO 2In 2O 3 show high arc erosion resistance and a good resistance against contact welding. By introducing certain additives,the AgSnO 2 materials,produced by the powder metallurgy technique(sintering and extrusion) can be modified in such a manner that contact resistance and over temperature behavior can be maintained low and stable over service life. Material transfer in DC operation is low. Contact materials of the AgSnO2 and AgSnO2In2O3 type are non-toxic and friendly to the environment.

Application Scope

Widely used in various kinds of contactors、relays、circuit breakers and switches, and so on.

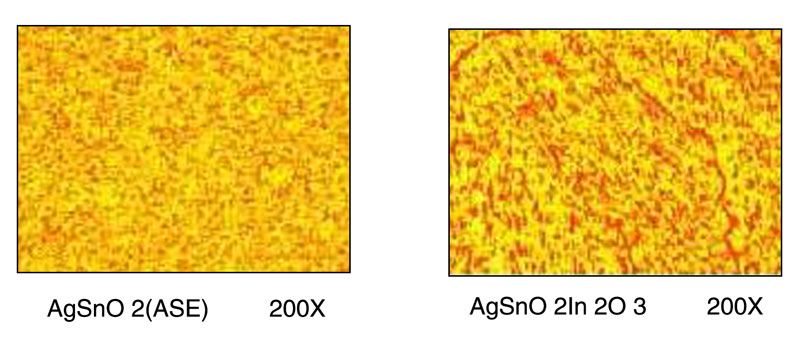

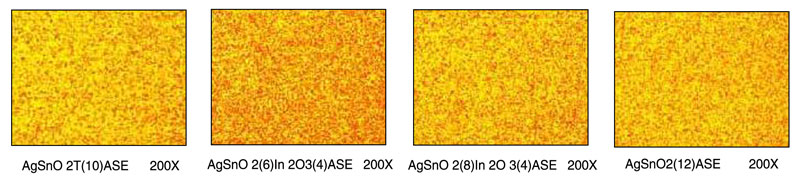

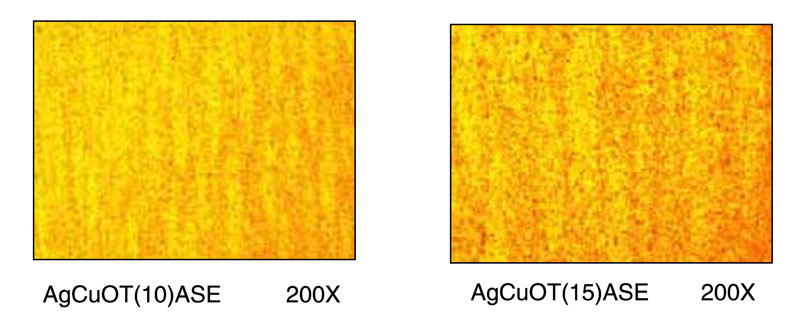

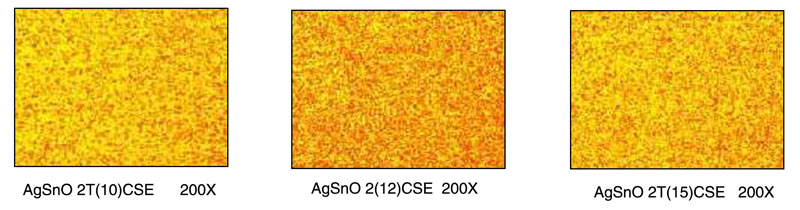

Microstructure

Material Properties

| AgSnO2(ASE) | AgSnO2In203 | |||||

| SnO2 Content(wt.%) | 8±1 | 10±1 | 12±1 | 6+ln 2O3(4) | 8+ln 2O3(4) | 9+ln 2O3(4) |

| Density (g/cm3) | ≥10.00 | ≥9.90 | ≥9.80 | ≥9.80 | ≥9.75 | ≥9.75 |

| Elec.Resisivity(μΩ · cm) | ≤2.30 | ≤2.40 | ≤2.50 | ≤3.30 | ≤3.40 | ≤3.50 |

| Hardness HV (Mpa) | ≥700 | ≥700 | ≥750 | ≥720 | ≥760 | ≥780 |

| Manufacturing process | Atomizing-Sintering-Extrusion | Internal Oxidation | ||||

Material Properties

Microstructure

Material Properties

Material Properties

| AgSnO 2T (10) I.O | AgSnO 2T(12) I.O | |

| Sno 2 Content (wt.%) | 10±1 | 12±1 |

| Density (g/cm3) | ≥9.96 | ≥9.91 |

| Elec.Resistivity(μΩ · cm) | ≤2.30 | ≤2.35 |

| Hardness HV (Mpa) | ≥950 | ≥900 |

| Tensile Strength (Mpa) | 305-360 | 305-345 |

| Elongation (%) | 18-30 | 18-30 |

Material Properties

Material Properties

| AgSnO 2 (10) CSE | AgSnO 2T (12) CSE | AgSnO 2T (15) CSE | |

| SnO2 Content(wt.%) | 10±1 | 12±1 | 15±1 |

| Density (g/cm³) | ≥9.90 | ≥9.85 | ≥9.65 |

| Elec.Resistivity(µΩ·cm) | ≤2.20 | ≤2.30 | ≤2.55 |

| Hardness HV (Mpa) | ≥800 | ≥800 | ≥950 |

| Tensile Strength(Mpa) | 230-285 | 230-285 | 250-300 |

| Elongation(%) | 18-30 | 18-30 | 18-30 |

Silver alloy wire (bonding silver wire), is currently the most suitable alternative to gold wire soldering consumables. In the LED package to play the role of wire c...

Electrical contact materials have a history of nearly 100 years, initially using pure silver, pure gold, pure platinum to make contact materials; the 1940s began to ...

Precision stamped parts, which are made with high-precision dies, complete the blanking process by positioning them in one clamping. The workpiece on the punching ma...

As a manufacturer of electrical metal stamping parts, we have an in-depth understanding of the design principles and characteristics of stamping parts, so we will ta...

Precision Metal Stamping, which are made with high-precision dies, complete the blanking process by positioning them in one clamping. The workpiece on the punching m...