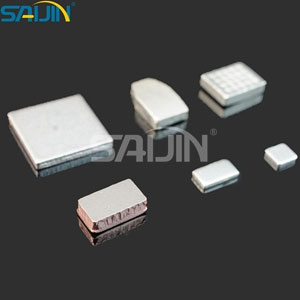

How does Silver Rivet Contact achieve on-off control of the circuit?

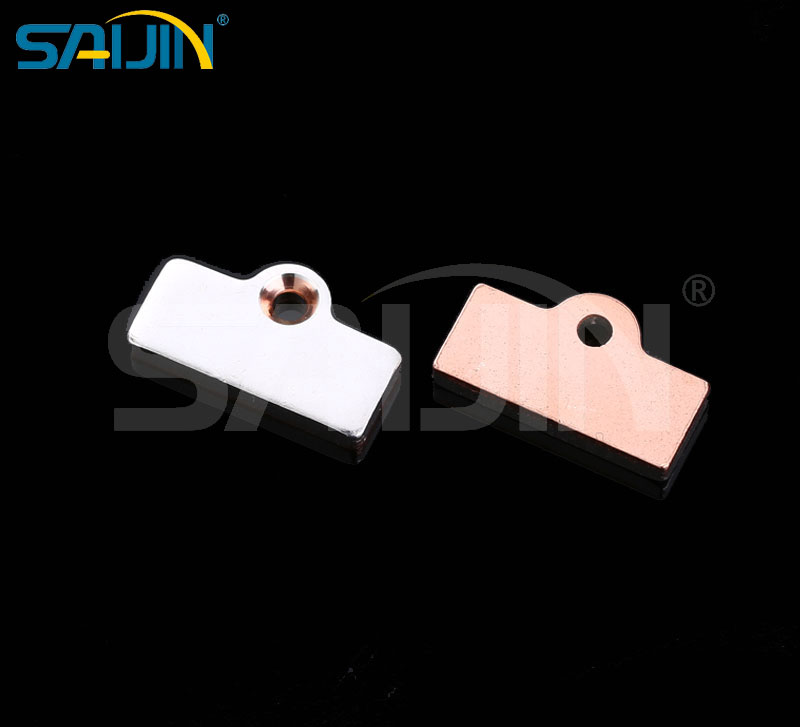

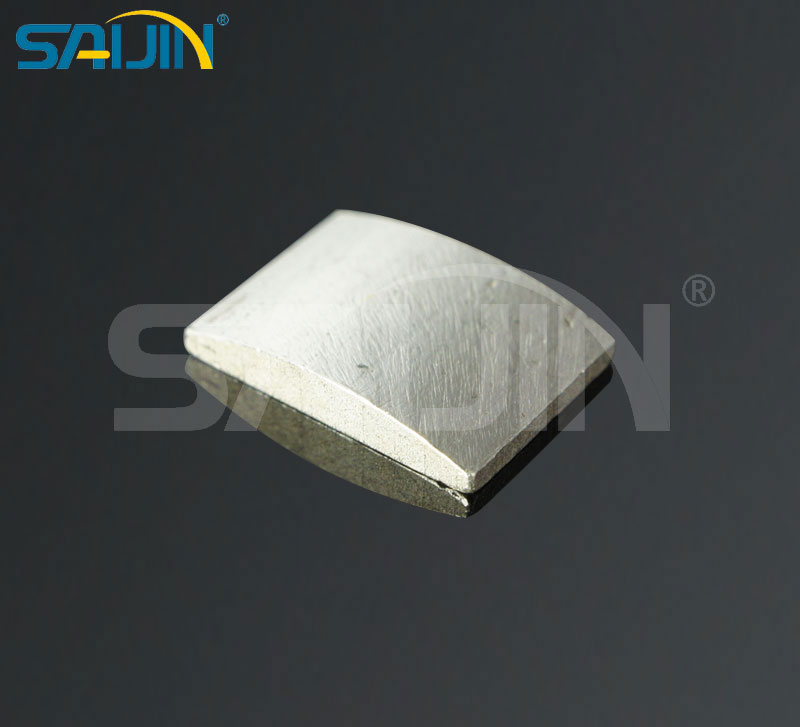

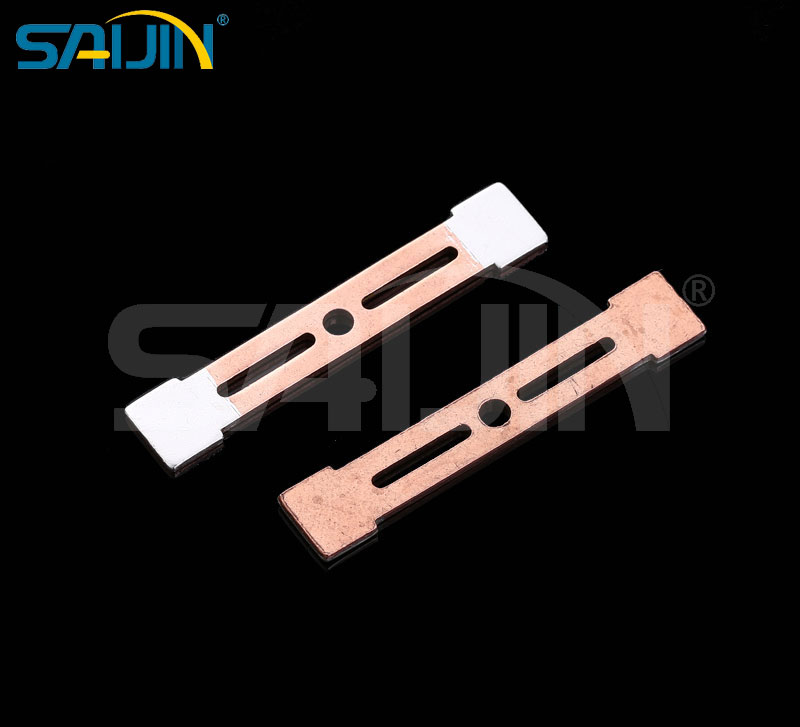

Silver Rivet Contact realize the on-off control of the circuit, mainly through their physical properties and the connection method in the circuit. The following are the specific implementation methods: