Electrical Contact Points: A Comprehensive Guide

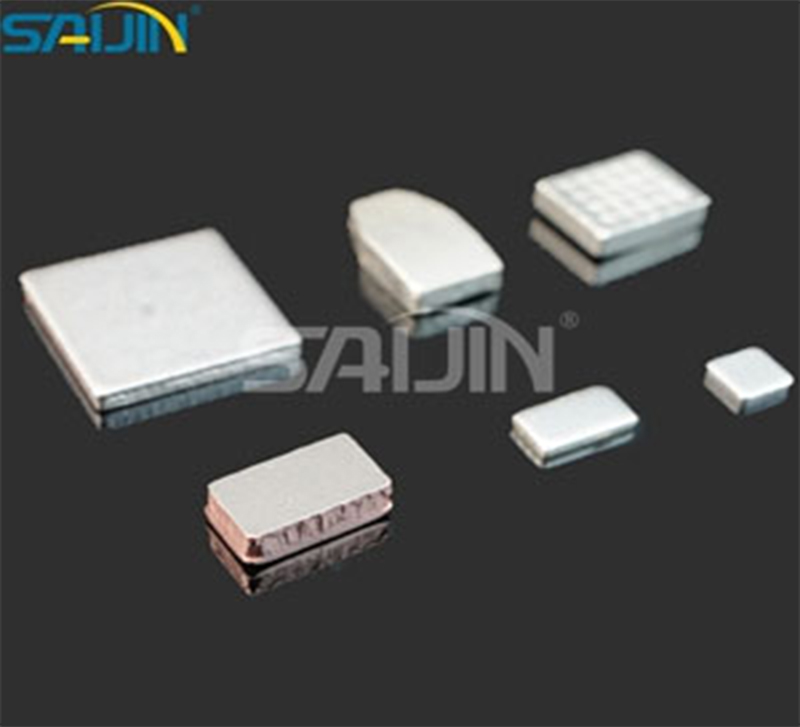

Electrical contact points are essential components that enable reliable electrical switching and current transmission, with performance determined by material selection, manufacturing quality, and proper d...