what is tungsten

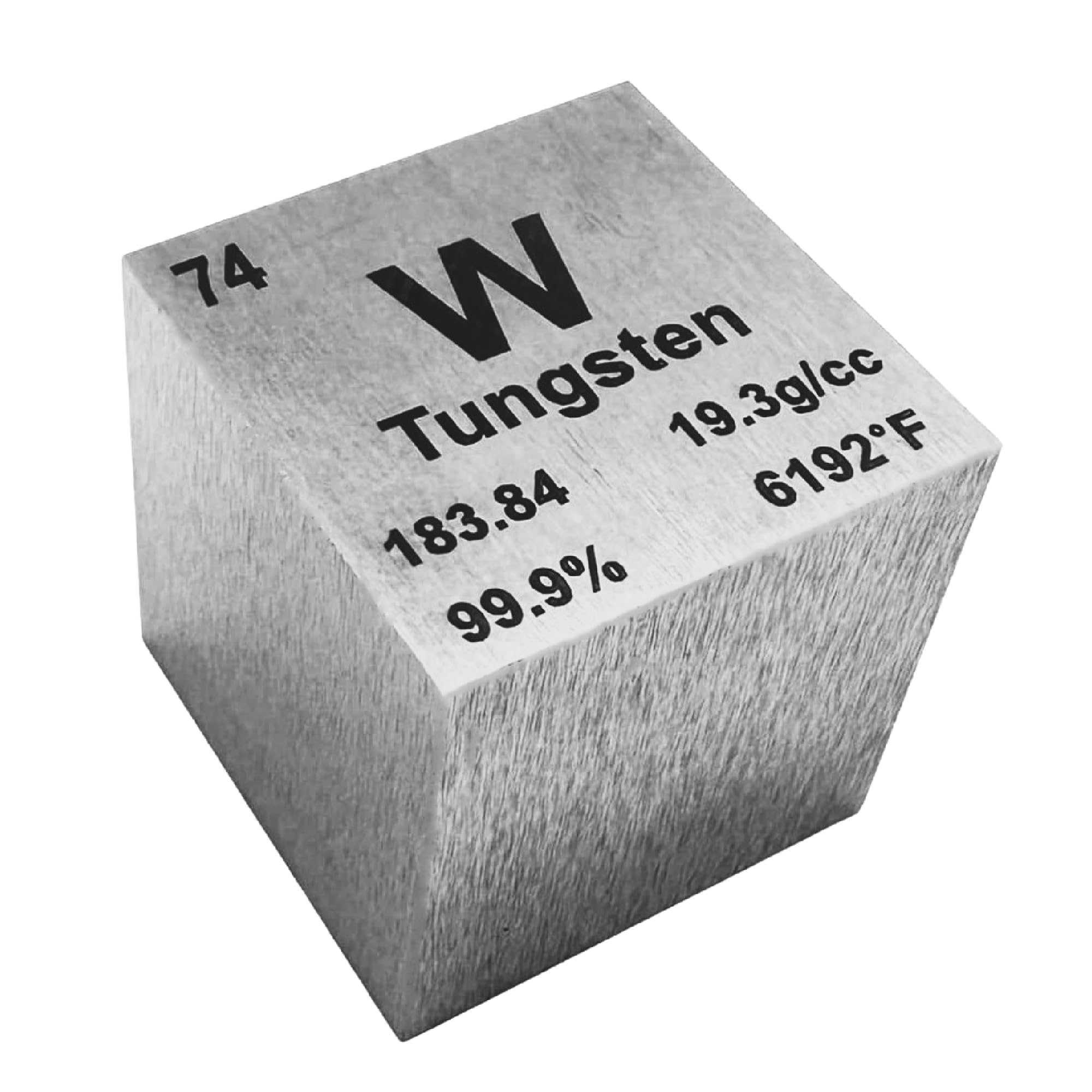

Tungsten, often recognized by its chemical symbol "W" (derived from the German word "Wolfram"), is a remarkable silvery-white metal renowned for its exceptional durability, hardness, and resistance to extreme heat. With an atomic number of 74, it stands out among elements for its unique combination of physical and chemical properties, making it indispensable in various industrial and technological applications.

Key Properties of Tungsten

1. High Melting Point: Tungsten boasts the highest melting point of all metals, reaching an impressive 3,422 °C (6,192 °F). This property makes it ideal for use in environments subjected to intense heat.

2. Density: As a heavy metal, tungsten has a density of 19.25 g/cm³, comparable to that of gold, contributing to its robustness.

3. Hardness: Ranking 9 on the Mohs hardness scale, tungsten is one of the hardest natural metals, second only to diamonds.

4. Corrosion Resistance: It withstands exposure to most chemicals and harsh environments, maintaining its integrity over time.

5. Tensile Strength: Tungsten can endure significant pulling forces without breaking, a trait crucial for structural applications.

Common Applications of Tungsten

Tungsten’s unique properties drive its use in diverse industries:

Electronics and Lighting: Its high melting point makes tungsten the primary material for incandescent light bulb filaments and heat-resistant components in electronics.

Aerospace and Aviation: Tungsten alloys are used in rocket nozzles, aircraft engine parts, and radiation shielding due to their heat and corrosion resistance.

Industrial Tools: Tungsten carbide, a superhard compound, is integral to cutting tools, drill bits, and abrasives for machining hard materials.

Military and Defense: Tungsten’s density makes it suitable for armor-piercing projectiles and counterweights in military equipment.

Medical and Radiation Protection: It is used in radiation shields for X-ray machines and cancer treatment equipment.

Why Are Tungsten Rivets Preferred in Certain Applications?

Tungsten rivets stand out in specialized fields for several key reasons:

Extreme Temperature Resistance: In high-temperature environments (e.g., aerospace engines or industrial furnaces), tungsten rivets maintain their strength without deforming, unlike many other metals.

High Strength-to-Weight Ratio: Despite their density, tungsten rivets offer exceptional tensile strength, making them ideal for applications requiring robust connections with minimal weight.

Corrosion and Wear Resistance: Tungsten’s ability to withstand chemical exposure and friction ensures long-term reliability in harsh conditions, such as marine or industrial settings.

Electrical and Thermal Conductivity: While tungsten is not the best conductor, its stability in high-energy environments makes it suitable for electrical contacts and thermal management components.

How Are Tungsten Rivets Manufactured?

The production of tungsten rivets involves precise engineering:

1. Powder Metallurgy: Tungsten powder is mixed with binders to form a malleable compound.

2. Compression Molding: The mixture is pressed into rivet-shaped preforms under high pressure to achieve initial density.

3. Sintering: Preforms are heated in a high-temperature furnace (below tungsten’s melting point) to fuse particles together, enhancing strength and durability.

4. Finishing and Machining: Rivets undergo grinding, polishing, and threading to meet specific dimensional and surface requirements.

5. Quality Testing: Each rivet is inspected for defects, hardness, and mechanical properties to ensure compliance with industry standards.

Conclusion

Tungsten’s unique blend of properties continues to make it a cornerstone of modern industry, driving innovation in fields from electronics to space exploration. Its ability to withstand the most demanding conditions ensures its relevance in advanced technological applications for years to come.

FAQ

Q1. What is tungsten primarily mined from?

A: Tungsten is extracted from minerals like wolframite and scheelite, primarily mined in countries such as China, Russia, and Canada.

Q2. Is tungsten toxic?

A: Tungsten has low toxicity in its pure form, but some compounds may pose health risks if inhaled or ingested. Proper safety measures are essential in industrial handling.

Q3. Can tungsten be recycled?

A: Yes, tungsten is highly recyclable. Scrap tungsten from manufacturing or used components is often reprocessed into new materials, reducing environmental impact.

Q4. Are there alternatives to tungsten in high-temperature applications?

A: While some ceramics and superalloys offer similar properties, tungsten remains unmatched for its combination of melting point, hardness, and cost-effectiveness in many scenarios.

Q5. How does tungsten contribute to green technology?

A: Tungsten’s durability and heat resistance support efficient energy conversion in renewable energy systems, such as high-temperature fuel cells and thermal storage devices.