What is an electrical connection point?

An electrical contact point is a conductive component within an electrical device that allows current to flow when it comes into contact with another conductive surface. It acts as a bridge that opens or closes an electrical circuit, enabling or interrupting the passage of electricity. Electrical contacts are essential in switches, relays, connectors, circuit breakers, and many other devices that rely on controlled electrical conduction.

Function of Electrical Contacts

The main function of an electrical contact is to establish, carry, and interrupt electrical current within a circuit. When two contact surfaces meet, they complete the circuit, allowing current to flow. When they separate, the circuit breaks, stopping the flow.

A good electrical contact must ensure:

Low contact resistance to minimize power loss.

High conductivity for efficient current transfer.

Durability and wear resistance to withstand repeated mechanical and electrical stress.

These functions are vital for reliable operation in both low-voltage control systems and high-power industrial applications.

Types of Electrical Contacts

Electrical contacts can be classified by their structure or function:

Stationary and Movable Contacts:

Common in switches and relays, one contact remains fixed while the other moves to open or close the circuit.

Make Contacts (Normally Open):

These contacts remain open until activated, closing the circuit when triggered.

Break Contacts (Normally Closed):

These stay closed and open when an electrical or mechanical force is applied.

Transfer Contacts (Changeover):

Used to switch between two circuits, commonly found in relays and control devices.

Sliding or Rotary Contacts:

Used in devices like potentiometers and rotary switches where movement maintains continuous electrical connection.

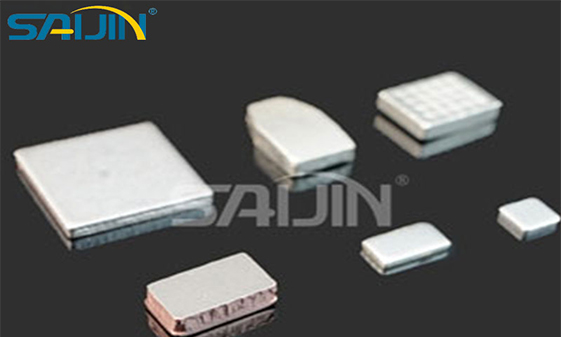

Materials Used in Electrical Contacts

Choosing the right contact material is crucial for performance and longevity. The most common materials include:

Silver (Ag): Excellent conductivity and low resistance, widely used in relays and switches.

Silver Alloys (AgCdO, AgNi, AgSnO₂): Improved arc resistance and hardness.

Copper (Cu): High conductivity but prone to oxidation; often plated or alloyed.

Gold (Au): Superior corrosion resistance, ideal for low-voltage or signal applications.

Tungsten (W) and Molybdenum (Mo): High melting points, suitable for heavy-duty and high-voltage contacts.

Material selection depends on factors like electrical load, mechanical wear, and environmental conditions.

Applications of Electrical Contacts

Electrical contacts are used across a wide range of industrial and consumer applications, including:

Switches and Relays: Control current flow in circuits.

Circuit Breakers and Contactors: Manage high-voltage or high-current loads safely.

Connectors and Sockets: Provide reliable connections between devices.

Automotive Systems: Control ignition, lighting, and power distribution.

Home Appliances and Electronics: Enable on/off control and signal transmission.

In modern technology, the performance of electrical contacts directly impacts the reliability and efficiency of entire systems.

Conclusion

An electrical contact is a fundamental component that ensures reliable current flow in electrical and electronic systems. Its function, material, and design determine the stability, safety, and efficiency of power transmission and control. From everyday household devices to complex industrial machinery, electrical contacts play a vital role in keeping modern technology connected and operational.