Electrical Contact Points: A Comprehensive Guide

In modern electrical and electronic systems, reliable control and transmission of electric current are essential for safety, efficiency, and performance. From simple household switches to complex industrial automation and power distribution equipment, electrical contact points serve as the physical interface that enables circuits to open, close, and transfer energy. Although often small in size, these components play a critical role in ensuring stable electrical connections, minimizing energy loss, and extending equipment lifespan.

What Are Electrical Contact Points?

Electrical contact points are conductive components used to make, carry, or break an electrical circuit. They typically consist of two or more conductive surfaces—one fixed and one movable—that come into contact to allow current flow and separate to interrupt it. Electrical contact points are fundamental elements in switches, relays, contactors, connectors, sockets, circuit breakers, and many other electrical and electronic devices, enabling controlled and reliable electrical connections.

Production Process of Electrical Contact Points

1. Material Selection: Common materials include copper and copper alloys, silver and silver-based alloys, gold or gold-plated metals, nickel coatings, and platinum-group metals for demanding environments. Material choice depends on conductivity, wear resistance, arc resistance, and cost.

2. Stamping or Cutting: Sheet metal contact points are often produced by high-speed stamping or laser cutting from metal strips, ensuring high efficiency and consistent dimensions.

3. Machining and Forming: Precision bending, milling, or turning processes are applied to achieve accurate contact geometry and mechanical tolerances.

4. Powder Metallurgy and Sintering: Composite contact materials, such as silver–tungsten, are manufactured using powder metallurgy to achieve superior arc resistance and durability.

5. Heat Treatment: Heat treatment processes improve mechanical strength, elasticity, and fatigue resistance, especially for spring-type contact components.

6. Surface Treatment and Plating: Contact points are often plated with silver, gold, or nickel to enhance conductivity, corrosion resistance, and service life.

7. Assembly and Joining: Contact elements are assembled with springs, carriers, and insulating components using welding, riveting, or brazing methods.

8. Inspection and Testing: Final inspection includes contact resistance testing, durability testing, temperature rise measurement, and visual inspection to ensure reliability.

Advantages of Electrical Contact Points

Excellent Electrical Conductivity

High-quality contact materials provide low contact resistance, ensuring efficient current transmission and reduced power loss during operation.

Reliable Switching Performance

Electrical contact points enable precise and repeatable circuit opening and closing, making them suitable for both control and protection applications.

Wide Load Adaptability

By selecting appropriate materials and contact structures, electrical contact points can handle a broad range of voltages and currents—from micro-signal switching to high-power applications.

Long Service Life

Optimized contact geometry, controlled contact force, and advanced surface treatments significantly reduce wear, oxidation, and arc damage, extending operational lifespan.

Strong Environmental Adaptability

Electrical contact points can be designed to withstand harsh conditions such as high temperatures, humidity, vibration, dust, and corrosive environments.

Flexible Design and Customization

Contact shape, size, material, plating, and spring force can be customized to meet specific application requirements and industry standards.

Cost-Effective and Scalable

Mature manufacturing processes allow electrical contact points to be produced efficiently in large volumes while maintaining consistent quality and competitive costs.

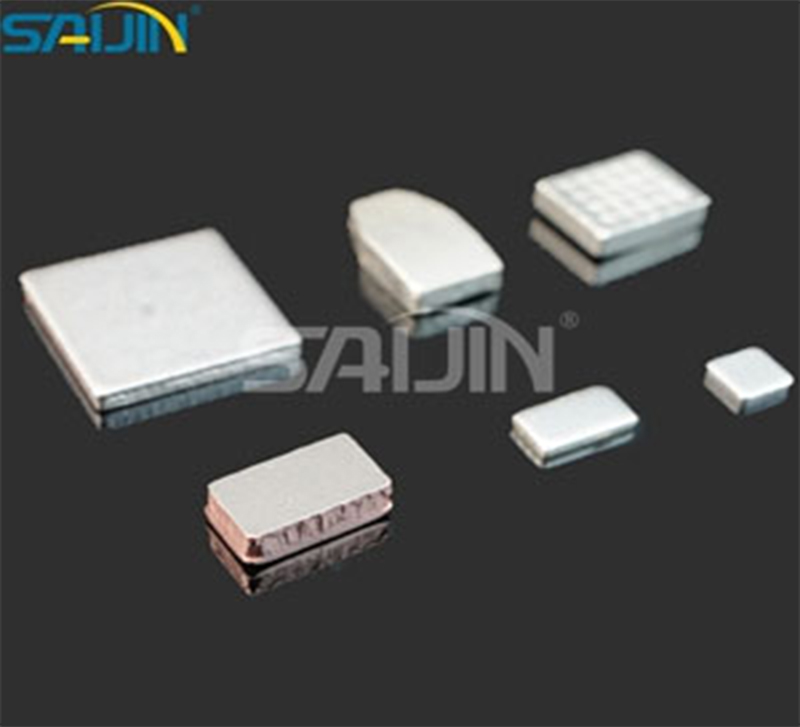

Main Types of Electrical Contact Points

1. Point Contacts: Small-area contact points commonly used in relays and miniature switches, offering concentrated contact pressure.

2. Surface (Plane) Contacts: Larger contact areas designed for higher current loads, commonly found in contactors and power switches.

3. Wiping or Sliding Contacts: Contacts that slide against each other during operation, helping remove oxide layers and maintain low resistance. Typical in connectors and sliding switches.

4. Rolling Contacts: Use rolling elements to reduce friction and wear, often applied in rotary or long-life switching mechanisms.

Electrical Contact Points Applications

Low-Voltage Control Devices: relays, push buttons, sensors, and control modules

Power Switching Equipment: contactors, circuit breakers, and power terminals

Connectors and Sockets: industrial connectors, automotive connectors, and consumer electronics interfaces

Motors and Generators: commutators and brush assemblies

Battery and Energy Storage Systems: battery terminals, spring contacts, and EV power contacts

Telecommunications and Instrumentation: signal relays, test contacts, and measurement equipment

Aerospace and Defense: high-reliability contact systems for harsh environments

Home Appliances and Consumer Electronics: plugs, sockets, and internal electrical connections

Industrial Automation: PLC interfaces, sensors, and robotic equipment connections

Summary

Electrical contact points play a critical role in controlling and transmitting electrical energy across virtually all electrical and electronic systems. Their performance depends on proper material selection, precise manufacturing processes, and suitable surface treatments. By matching the contact design and material to the specific application—whether low-level signal switching or high-current power control—manufacturers can ensure long service life, stable performance, and high reliability.

FAQ

Q: What factors affect the lifespan of electrical contact points?

A: Electrical load, switching frequency, contact material, contact pressure, and environmental conditions all influence contact lifespan.

Q: Why are gold-plated contact points used in signal applications?

A: Gold plating offers excellent corrosion resistance and stable low contact resistance, making it ideal for low-voltage, low-current signals.

Q: How can arc damage be reduced in electrical contact points?

A: Arc-resistant materials, proper contact design, fast switching action, and arc suppression circuits help minimize arc damage.

Q: Can worn or oxidized contact points be reused?

A: Light oxidation may be cleaned, but severely worn or damaged contact points should be replaced to ensure safety and reliability.

Q: How do I choose the right contact material?

A: Selection should be based on electrical load, operating environment, mechanical requirements, expected lifespan, and cost considerations.